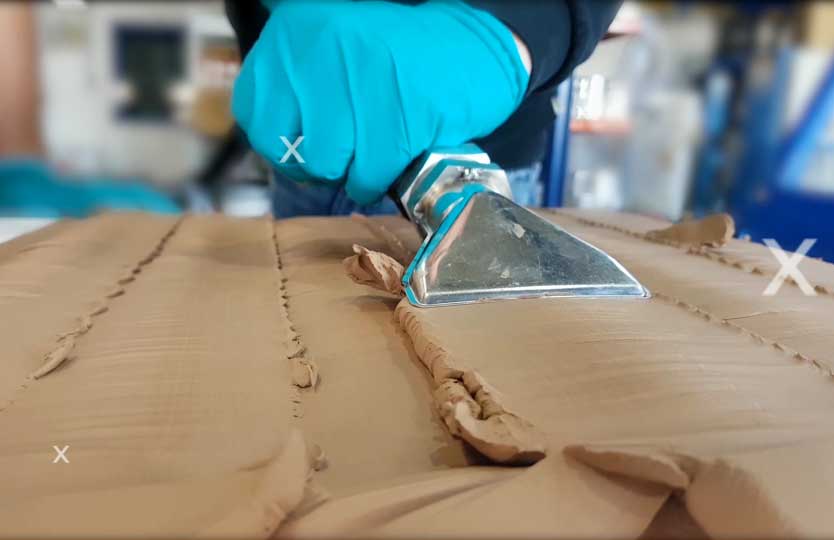

Next generation 3D modelling After 2 years of development and extensive testing we present our Clay Application Machine!

Product launch

Automated and manual clay processing with Clay Application Machine

Test machine with the following specification

Saying goodbye to manual clay handling The TARTLER GROUP'S new clay application machine is revolutionising model making

A fundamental paradigm shift is currently taking place in design model making: Where craftsmanship and one’s keen sense of proportion previously set the tone for more than a hundred years, largely automated systems will soon be taking over the conditioning and processing of clay (plasticine). The TARTLER GROUP is now proving to be the technological leader in this field, as, after two years of development, it presents one of the first system solutions for the machine dosing and application of clay: The Clay Application Machine CAMA 01, which enables automotive and industrial designers to gain entry to the semi or fully automated clay styling process. The system is supplied by the subsidiary SOMATA.

Interested? Give us a call!

+49 6061 9672-0

You prefer writing an email?

Please use the contact form below.